23rd May 2022

The development of our Life Cast Arm Haemorrhage Control Simulator (HCS)

So, what is it and what does it do?

In 2021, the team at TraumaSim Group took on the challenge to design & manufacture a brand new Haemorrhage Control Simulator as a lifecast arm. We combined our knowledge of haemorrhage control and silicone artistry and are proud to have developed a product that reflects the medical realism we are known for.

The Lifecast Arm features 2 x wounds being a junctional laceration near the armpit that is ideal for wound packing and a laceration across the radial artery on the wrist that can be used for tourniquet application – being the ideal combined unit for bleeding control training!

Wound packing and applying a tourniquet to an injured person are both physically and mentally traumatic for any First Responder. Knowing that they are inflicting further pain on the casualty in order to save their life can make application in a real life situation extremely difficult. Hence the haemorrhage control simulator that enables students to practise repeatedly in a safe environment.

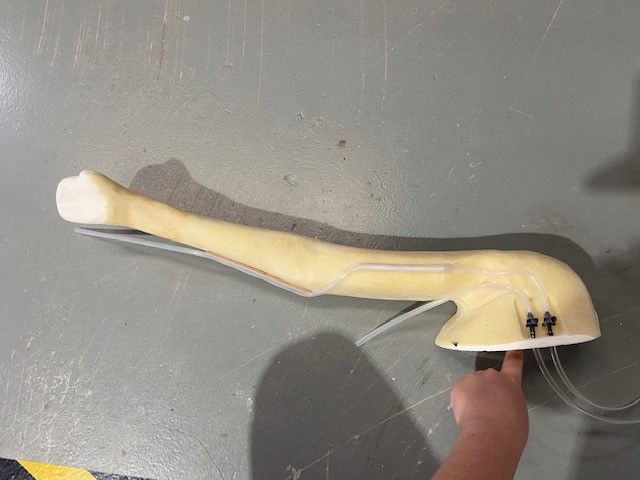

This device also teaches first aiders that, in order to save a life, two visually similar wounds must be treated differently depending on where they are placed on the body. When a tourniquet is applied correctly to the arm, the flexible plumbing within the silicone skin will restrict blood flow and stop the bleed of the forearm laceration. The laceration to the upper arm however is purposefully placed so that a tourniquet will not restrict blood flow. In this instance, the first aider must use wound packing techniques to stop the bleed.

This product can be clamped or bolted to a table, with controlled blood flow connected to a 5L reservoir. The two bleeding wounds can be operated independently or together, allowing the user to place themselves in differing hypothetical emergency situations. If the casualty is bleeding from both wounds, which would the user treat first?

Medical grade silicone is used in the arm to provide a realistic human flesh look and feel, and is strong enough to demonstrate the realistic amount of physical force required to effectively apply a tourniquet, or the pressure required to pack the wound and stop a heavy bleed. See video below:

How does the arm differ from our other products?

TraumaSim Group have a varied range of haemorrhage control simulators as well as haemostatic clotting trainers that will assist any trainer looking to teach the Advanced First Aid curriculum. The use of these training aids comply with national standards as defined by the Australia Resuscitation Council (ARC) and Australia Skills Quality Authority (ASQA).

A portion of our more visually graphic products, such as the severed limb Emergency Tourniquet Trainer, have been developed in conjunction with the Australian Defence Force and other tactical based Emergency Response teams. Taking a different approach, the Lifecast Arm, moulded from one of our very own staff, presents a more realistic simulator for general businesses and the public.

Differing from our Emergency Tourniquet Trainer, this unit highlights that tourniquets are not only effective for amputations but can also be applied to mitigate any major blood loss to a haemorrhaging limb. This type of first aid response for an arterial bleed has been trialled and tested over many years, and current research shows that it is the most effective approach to stop the bleed when packing is not enough.

Read more here: https://www.facs.org/media/press-releases/2018/tourniquet040418

How was the arm developed and what challenges did we face?

The development of the life cast arm began as an idea – to produce a more anatomically realistic haemorrhage control simulator that teaches first aiders to mitigate heavy bleeding using correct tourniquet application and wound packing techniques. We conceptualised an arm with two deep lacerations – one bleeding wound in the forearm that can be stopped with a tourniquet and a second bleeding wound placed near the armpit that can be stopped with wound packing techniques.

In order to create a foolproof product, many hours were devoted to planning the inner mechanics of the arm and extensive testing was required to ensure it functioned correctly. Before beginning construction, we drafted a 37-page development plan!

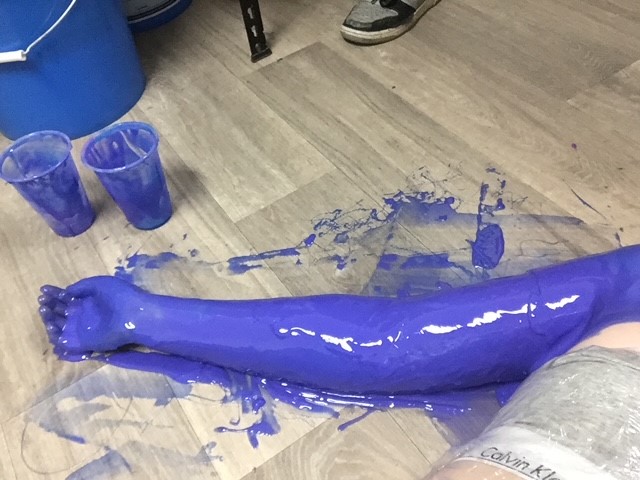

The construction process begins with a life cast, made using silicone and plaster bandage. We then filled this life cast with a liquified oil-based clay and demoulded it once it had cooled. The two wounds were sculpted into this solid clay arm and that became the shape that you see in our product.

A 3-part fiberglass mould later, and we had the outer shell of the mould. The most complicated part of the process for this kind of product, is working backwards to develop the inner core of the product. We used our outer mould of the arm to measure inwards an even thickness on all sides, that would become the “skin”. Using these measurements, we were able to create a solid inner core that acts as the “bones” of the arm and can withstand the strength of a RAT and CAT tourniquet

Here is where the trouble shooting comes in. Product development always has complications, and we had a few challenges to face. How do we replicate the exact density of human skin, so that the tourniquet stops blood flow with the right amount of pressure? How do we make the arm easy to use? How do we make the arm strong enough to avoid breakage under pressure?

It took two full runs of the product development from life casting to pouring in order to smooth out all the kinks in the process. Trial and error is the key to success, and with a fair few errors we have created the life cast arm haemorrhage control simulator, ta-da!

As with all of our products, this Lifecast Arm is available in 11 x different skin pigments truly allowing diversity in your simulation training. For more information on this unit, check it out in our store (HCS01 Lifecast Arm) or contact the team today on 1300 411 080 or via info@traumasim.com.au.